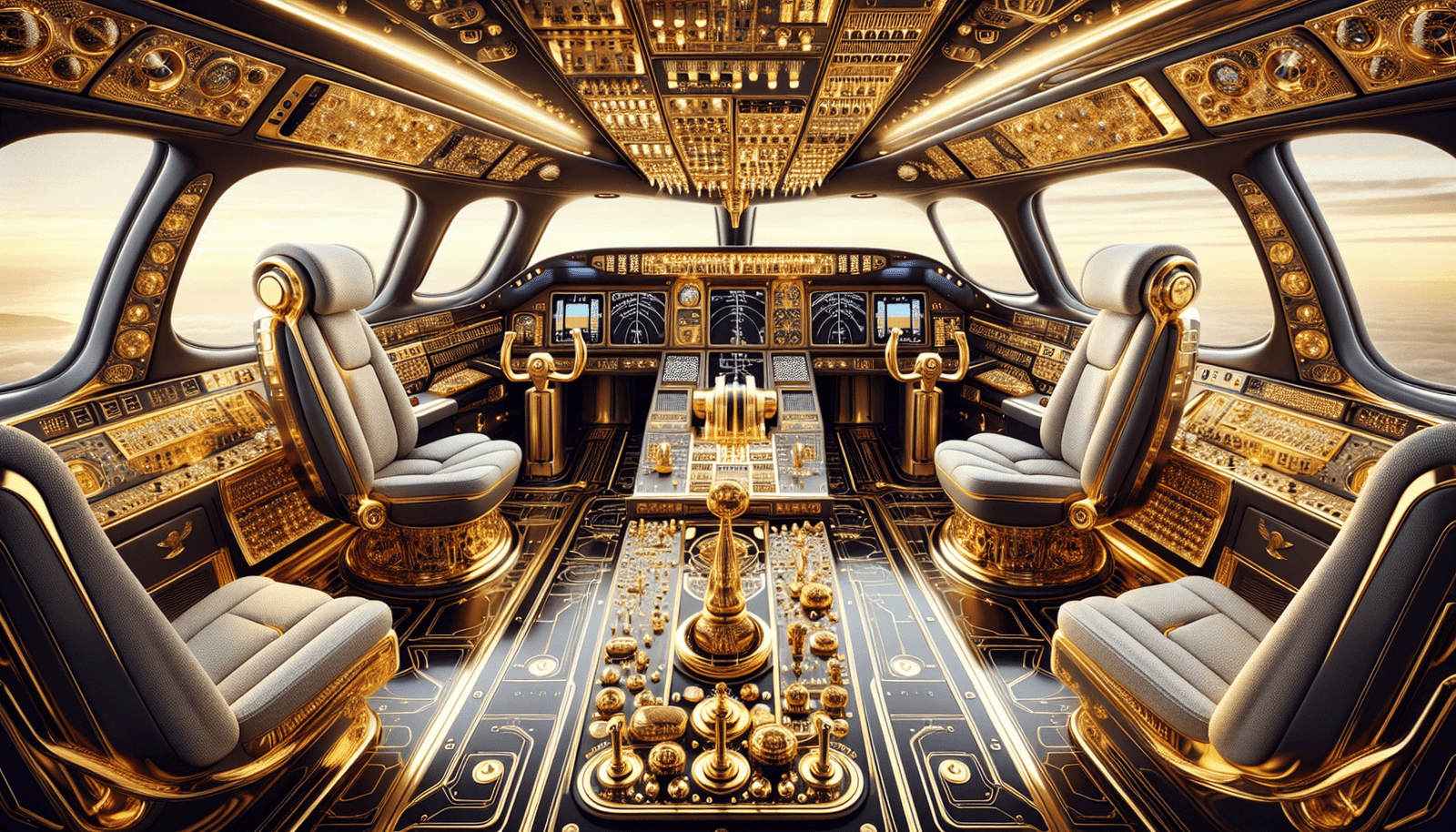

Welcome to a fascinating article on the use of gold in modern aviation! Gold, a precious metal known for its beauty and value, is not just limited to jewelry and investments. In recent years, gold has been integrated into various components of aircrafts, from wiring and connectors to avionics and coating materials. This innovative use of gold in aviation has not only improved the performance and durability of aircrafts, but also sparked new advancements in the aerospace industry. Let’s explore the role of gold in modern aviation and how it is shaping the future of air travel. Have you ever wondered about the role that gold plays in modern aviation? You may be surprised to learn about the various ways in which this precious metal is integrated into the technology and equipment used in aircraft. Let’s explore the fascinating world of gold in aviation together!

The Use of Gold in Avionics

You might not know it, but gold is a key component in the avionics systems that power modern aircraft. Avionics refer to the electronic systems used in aircraft for communication, navigation, and overall control. Gold is used in avionics due to its superior conductivity and corrosion resistance, making it an ideal material for ensuring reliable and efficient performance.

Gold Plating for Connectors

One common application of gold in avionics is in the plating of electrical connectors. Gold is an excellent conductor of electricity and is highly resistant to corrosion, making it perfect for ensuring stable and uninterrupted electrical connections in critical systems. The use of gold-plated connectors helps prevent signal degradation and interference, ensuring the smooth operation of avionics systems.

Gold Bonding Wires

Gold is also used in the manufacture of bonding wires that connect semiconductor chips to the circuitry in avionics systems. These wires are crucial for transmitting electrical signals efficiently and reliably within the systems. Gold bonding wires are preferred for their durability, conductivity, and ability to withstand high temperatures, ensuring the long-term performance of avionics components.

Gold Coatings for Antennas

In addition to its use in electrical components, gold is often applied as a coating on antennas used in communication and navigation systems in aircraft. Gold coatings provide enhanced conductivity and resistance to corrosion, ensuring optimal performance and longevity of the antennas. This application of gold helps maintain clear and reliable communication between the aircraft and ground control, contributing to the safety and efficiency of flights.

The Role of Gold in Engine Technology

Gold plays a crucial role in the development and operation of aircraft engines, where its unique properties are leveraged to enhance performance and reliability. Whether in propulsion systems or auxiliary power units, gold is utilized in various forms to enable efficient and safe aviation operations.

Gold Alloys in Engine Bearings

One notable application of gold in aviation engines is in the form of gold alloys used in engine bearings. These bearings are crucial components that support rotating parts within the engine, such as shafts and gears, ensuring smooth and efficient operation. Gold alloys are preferred for their high strength, low friction, and resistance to wear, making them essential for the reliable performance of aircraft engines.

Gold Coating for Engine Components

Gold coatings are also used in engine components that are subject to high temperatures, such as turbine blades and combustion chambers. The high thermal conductivity of gold helps dissipate heat effectively, protecting the components from overheating and reducing the risk of engine failure. Gold coatings contribute to the durability and performance of engine parts, ensuring the safe and efficient operation of aircraft propulsion systems.

Gold Sensors for Engine Monitoring

Another innovative use of gold in aviation engines is in the production of sensors for monitoring various parameters, such as temperature, pressure, and vibration. Gold is preferred for sensor applications due to its excellent electrical conductivity and resistance to corrosion, making it ideal for accurate and reliable data collection. Gold sensors play a critical role in ensuring the proper functioning and maintenance of aircraft engines, helping to prevent potential issues and optimize performance.

Gold in Structural Materials for Aircraft

Gold is not just limited to electronic or mechanical components in aviation – it is also utilized in structural materials that contribute to the strength, durability, and safety of aircraft. From coatings on exterior surfaces to composite materials in construction, gold enhances the performance of aircraft while providing essential protective properties.

Gold Alloys for Corrosion Resistance

Gold alloys are commonly used in the production of structural components for aircraft, such as fasteners, hinges, and brackets. These alloys are chosen for their exceptional corrosion resistance, preventing degradation and structural damage caused by environmental factors like moisture, salt, and chemicals. The use of gold alloys in structural materials helps prolong the lifespan of aircraft and maintain their structural integrity over time.

Gold Coatings for Exterior Surfaces

Gold coatings are applied to exterior surfaces of aircraft to provide protection against corrosion, abrasion, and UV radiation. These coatings not only enhance the aesthetic appeal of aircraft but also play a crucial role in extending their service life and reducing maintenance requirements. Gold coatings offer superior resistance to environmental factors, ensuring the long-term durability and performance of aircraft in diverse operating conditions.

Gold-Plated Composite Materials

Innovations in aerospace materials have led to the development of composite materials that incorporate gold-plated fibers or particles. These materials exhibit enhanced strength, stiffness, and thermal properties compared to conventional materials, making them ideal for use in structural components of aircraft. Gold-plated composite materials contribute to the lightweight design, fuel efficiency, and overall performance of modern aircraft, while ensuring durability and safety in extreme conditions.

The Environmental Impact of Gold in Aviation

As we marvel at the diverse applications of gold in aviation technology, it’s essential to consider the environmental impact of its extraction and use in the aerospace industry. Sustainable practices and responsible sourcing are critical to minimizing the ecological footprint of gold production and ensuring a greener future for aviation.

Responsible Mining and Recycling Practices

Gold mining can have adverse environmental effects, including deforestation, habitat destruction, and water pollution. To address these concerns, aviation industry stakeholders are increasingly prioritizing responsible mining practices and promoting the recycling of gold from electronic waste and discarded aircraft components. Recycling gold reduces the need for new mining activities and minimizes the environmental impact of gold production, contributing to sustainable resource management.

Eco-Friendly Coating Technologies

Advancements in eco-friendly coating technologies are reducing the environmental impact of gold applications in aviation. Water-based coatings, powder coatings, and other sustainable alternatives are being developed to replace traditional solvent-based coatings and reduce emissions of volatile organic compounds (VOCs). These environmentally friendly coatings offer comparable performance to gold coatings while minimizing the carbon footprint and toxicity associated with conventional coating processes.

Lifecycle Assessment of Gold Applications

A comprehensive lifecycle assessment of gold applications in aviation is essential for understanding the environmental impacts associated with its use. By evaluating the entire lifecycle of gold-containing products, from extraction and processing to disposal and recycling, aviation industry experts can identify opportunities for improving resource efficiency, reducing energy consumption, and minimizing waste generation. Lifecycle assessments help optimize the environmental performance of gold in aviation and promote sustainable practices across the industry.

Conclusion

In conclusion, the integration of gold in modern aviation extends far beyond its status as a valuable commodity – it is a critical enabler of advanced technology, innovation, and safety in the aerospace industry. From avionics and engine technology to structural materials and environmental sustainability, gold plays a multifaceted role in enhancing the performance and reliability of aircraft while meeting the demands of a dynamic aviation landscape. By recognizing the significance of gold in aviation and embracing responsible practices, we can ensure a brighter future for air travel that prioritizes efficiency, safety, and sustainability. So, the next time you board a plane, you can appreciate the hidden contributions of gold that make your journey possible – soaring to new heights with the brilliance of this precious metal.