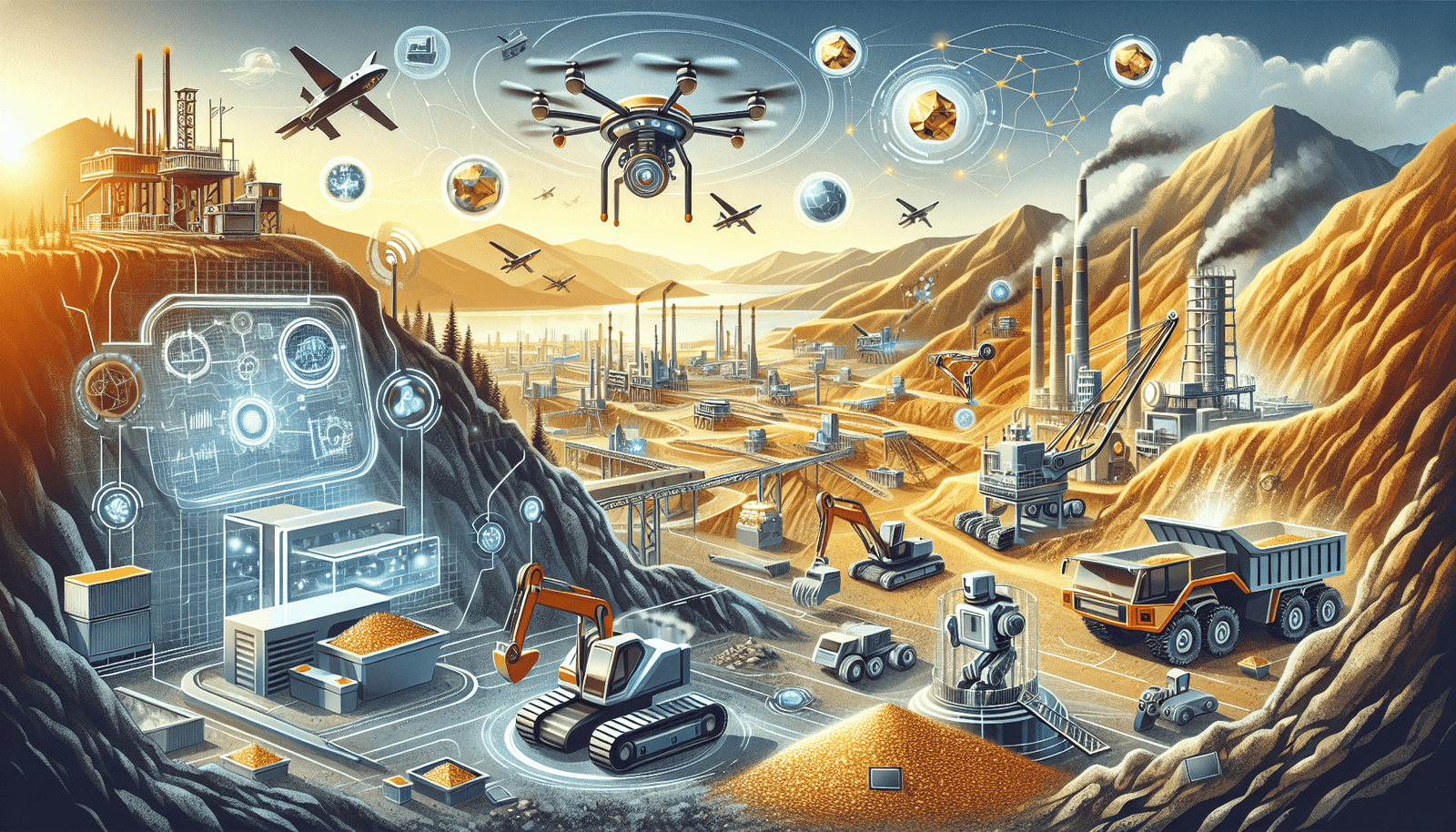

Imagine a world where the future of gold mining is not in human hands, but in the clutches of innovative robots. Picture sleek machines seamlessly navigating treacherous tunnels, tirelessly extracting valuable resources from Mother Earth’s depths. In this exciting article, we will explore the thrilling possibilities that lie ahead for the mining industry as it embraces the advancements of robotics. From increased safety measures to enhanced efficiency, the future of gold mining is about to undergo a fascinating transformation. Get ready to witness the dawn of a new era as we delve into the potential of robotic innovations in gold mining.

Introduction to Robotic Innovations in Gold Mining

Robotic innovations in gold mining refer to the use of advanced technologies and automated systems to improve efficiency, safety, and productivity in gold mining operations. These innovations involve the integration of robotics, artificial intelligence (AI), machine learning, and advanced sensor technologies to perform various tasks traditionally done by human miners. By harnessing the power of automation and intelligent systems, the gold mining industry is poised to undergo a significant transformation.

Definition of Robotic Innovations in Gold Mining

Robotic innovations in gold mining encompass a wide range of technologies and applications. These include autonomous drilling systems, advanced sensor technologies, remote-controlled robotic vehicles, 3D mapping and modeling, and machine learning algorithms. These innovations aim to replace or augment human labor in various stages of the gold mining process, from exploration to extraction and processing. By leveraging these technologies, mining companies can enhance safety, boost productivity, reduce environmental impact, and access previously unreachable or hazardous areas.

Historical Overview of Robotic Innovations in Gold Mining

The history of robotic innovations in gold mining dates back several decades. In the early 2000s, the industry witnessed the introduction of autonomous drilling systems that could accurately and efficiently drill boreholes without human intervention. This marked a significant milestone in the automation of mining operations. Over the years, advancements in AI, machine learning, and robotics have revolutionized various aspects of gold mining, leading to improved safety, increased efficiency, and enhanced productivity.

Benefits of Robotic Innovations in Gold Mining

Increased Safety for Miners

One of the key advantages of robotic innovations in gold mining is the improved safety for miners. Mining can be a dangerous profession, with potential hazards such as cave-ins, toxic gases, and accidents involving heavy machinery. By deploying robotic systems, mining companies can minimize the risks associated with human labor. Robotic vehicles can be used to perform tasks in hazardous environments, reducing the exposure of miners to dangerous conditions. Additionally, advanced sensors and AI algorithms can detect potential dangers and alert workers, enabling them to take preventive measures.

Efficiency and Productivity Improvements

Robotic innovations in gold mining also lead to significant efficiency and productivity improvements. Automated drilling systems, for example, can operate continuously without the need for breaks or rest, resulting in faster and more efficient drilling processes. Machine learning algorithms can analyze large volumes of data to optimize mining operations, identifying patterns and making accurate predictions to enhance productivity. With robots performing repetitive and labor-intensive tasks, human workers can focus on more complex and strategic activities, leading to increased overall efficiency.

Lower Environmental Impact

Robotic innovations in gold mining have the potential to significantly reduce the environmental impact of mining operations. Traditional mining processes often involve the use of large amounts of water and chemicals, leading to ecosystem disturbance and water pollution. Robotic systems can be designed to minimize these impacts by optimizing resource usage and implementing more precise and targeted exploration and extraction techniques. Additionally, the use of alternative energy sources and efficient machinery can reduce the carbon footprint of mining operations, contributing to a more sustainable approach.

Access to Previously Unreachable Areas

Another benefit of robotic innovations in gold mining is the ability to access previously unreachable or hard-to-reach areas. Robotic vehicles, equipped with advanced sensors and navigation systems, can operate in challenging terrains or confined spaces where human miners may face difficulties. These vehicles can explore and extract gold from remote or inaccessible regions, opening up new possibilities for discoveries and resource extraction. Furthermore, the use of drones and unmanned aerial vehicles (UAVs) can provide real-time aerial surveillance and mapping, allowing miners to analyze and plan their operations more effectively.

Current Challenges and Limitations

While robotic innovations in gold mining hold great promise, they also face certain challenges and limitations that need to be addressed for widespread adoption.

Cost and Feasibility of Implementing Robotic Innovations

One significant challenge is the cost and feasibility of implementing robotic innovations in gold mining. Developing and deploying robotic systems can require substantial upfront investment and pose financial risks for mining companies. The costs associated with research and development, training personnel, and maintaining the technology can be significant, particularly for smaller mining operations. Determining the return on investment and assessing the long-term viability of these technologies is crucial for mining companies considering the implementation of robotic innovations.

Technical Limitations and Reliability Issues

Robotic innovations in gold mining also face technical limitations and reliability issues. The harsh and unpredictable conditions of mining environments can put heavy strain on robotic systems, affecting their performance and reliability. Extreme temperatures, vibration, dust, and moisture can impact the functionality of sensors, machinery, and communication systems. Ensuring the robustness and durability of these technologies is essential to prevent breakdowns and maintain continuous operation. Furthermore, addressing the challenges of remote operations and communication in underground mining environments presents additional technical complexities that need to be overcome.

Regulatory Hurdles and Public Acceptance

Another important challenge is navigating the regulatory landscape and gaining public acceptance for robotic innovations in gold mining. Mining operations are subject to stringent regulations and oversight to ensure safety, environmental sustainability, and ethical practices. Introducing robotic systems into these operations may require updates to existing regulations or the creation of new ones to address the unique characteristics of automated and AI-driven technologies. Additionally, gaining public trust and acceptance for the use of robots and AI in mining requires effective communication and engagement with communities, stakeholders, and regulatory bodies.

Emerging Technologies in Robotic Innovations

Despite the challenges, several emerging technologies show great potential in advancing robotic innovations in gold mining.

Autonomous Drilling Systems

Autonomous drilling systems represent a significant advancement in robotic innovations in gold mining. These systems can operate independently, using advanced algorithms and real-time data analysis to optimize drilling processes. By removing the need for manual drilling, these systems can improve accuracy, speed, and operational efficiency while reducing human error and ensuring consistent results. Autonomous drilling systems also have the potential to increase safety by minimizing exposure to drilling hazards and reducing potential injuries.

Advanced Sensor Technologies

Advanced sensor technologies play a critical role in robotic innovations in gold mining. These sensors can be used to collect and analyze a wide range of data, such as geophysical information, temperature, humidity, and air quality. By continuously monitoring the mining environment, these sensors can detect potential risks, identify areas of high mineralization, and provide valuable insights for decision-making. Additionally, sensors can be integrated into robotic vehicles to enhance navigation, obstacle detection, and mapping capabilities, enabling precise and efficient exploration and extraction operations.

Remote-Controlled Robotic Vehicles

Remote-controlled robotic vehicles offer increased flexibility and accessibility in gold mining operations. These vehicles can be operated remotely by human operators, allowing them to navigate challenging terrains or hazardous environments without the need for human presence. Equipped with cameras, manipulator arms, and advanced communication systems, these vehicles can perform a wide range of tasks, including mapping, drilling, and sample collection. Remote-controlled robotic vehicles enhance safety by minimizing the exposure of human operators to dangerous conditions and enable efficient exploration and extraction in remote or hard-to-reach areas.

3D Mapping and Modeling

3D mapping and modeling technologies enable detailed and accurate visualization of mining sites, providing valuable insights for planning and decision-making. By capturing data from multiple sources, such as drones, laser scanners, and advanced imaging technologies, these systems can create highly detailed 3D representations of mining environments. Robotic systems can utilize these models for path planning, resource estimation, and virtual simulations, enhancing the efficiency and precision of mining operations. Furthermore, 3D mapping and modeling technologies can support environmental monitoring and impact assessment, ensuring sustainable mining practices.

Machine Learning and Artificial Intelligence

Machine learning and artificial intelligence algorithms are revolutionizing the capabilities of robotic innovations in gold mining. These algorithms can analyze vast amounts of data, identify patterns, and make accurate predictions, enabling proactive decision-making and optimization of mining processes. Machine learning algorithms can be used to optimize drilling parameters, predict potential risks, and improve operational efficiency. Additionally, AI-powered robotic systems can adapt to changing conditions, learn from previous experiences, and continuously improve their performance. As AI technologies advance, the integration of machine learning and robotics will further enhance the capabilities and effectiveness of gold mining operations.

Use Cases and Success Stories

Several use cases and success stories showcase the practical applications and benefits of robotic innovations in gold mining.

Robotic Mining Operations in Australia

In Western Australia, Rio Tinto, one of the world’s largest mining companies, has been at the forefront of robotic innovations in gold mining. The company has successfully implemented autonomous drilling systems, advanced sensors, and remote-controlled robotic vehicles in its mining operations. These technologies have resulted in improved safety, increased productivity, and reduced costs. By leveraging robotic innovations, Rio Tinto has been able to access previously inaccessible ore bodies and optimize resource utilization, contributing to sustainable and efficient mining practices.

Automated Gold Exploration in Remote Areas

Robotic innovations in gold mining have also enabled automated exploration in remote and inaccessible areas. Traditional exploration methods often involve extensive fieldwork and manual sampling, which can be time-consuming and costly. Robotic systems equipped with advanced sensors and navigation capabilities can efficiently collect geophysical data, analyze mineral composition, and identify potential gold deposits. By automating the exploration process, mining companies can save time and resources, enabling more focused and cost-effective operations in challenging terrains.

Future Trends and Developments

The future of robotic innovations in gold mining holds exciting possibilities and transformative developments.

Integration of Robotics with Data Analytics

The integration of robotics with data analytics is set to revolutionize the gold mining industry. By combining the power of advanced robotics and machine learning algorithms, mining companies can collect and analyze vast amounts of real-time data to improve operational efficiency, optimize resource allocation, and reduce costs. These data-driven insights can help identify potential risks, detect anomalies, and enable predictive maintenance of robotic systems. The integration of robotics with data analytics has the potential to unlock new levels of productivity and sustainability in gold mining.

Miniaturization and Swarm Robotics

Miniaturization and swarm robotics are emerging trends that offer exciting opportunities in gold mining. Miniature robotic systems, equipped with advanced sensors, can navigate narrow tunnels and perform intricate tasks in underground mining environments. These miniaturized robots can provide real-time data collection, inspection, and maintenance services, enhancing safety and efficiency. Swarm robotics, on the other hand, involves the coordination of multiple robotic agents to perform complex tasks. By leveraging the collective intelligence and capabilities of swarms, mining companies can achieve greater efficiency, scalability, and redundancy in their operations.

Robotic Mining on Other Celestial Bodies

The exploration of other celestial bodies, such as the Moon and Mars, presents unique opportunities for robotic innovations in gold mining. Robotic systems can be deployed to conduct resource prospecting and extraction on these celestial bodies, enabling the mining of precious metals and resources. The utilization of autonomous drilling systems, advanced sensor technologies, and AI algorithms can unlock the potential of extraterrestrial mining and pave the way for future space exploration and colonization.

Impact on Jobs and Workforce

The introduction of robotic innovations in gold mining will undoubtedly transform job roles and skill requirements in the industry.

Transformation of Job Roles and Skill Requirements

As robotic systems become more prevalent in gold mining operations, the nature of job roles will evolve. The demand for workers with expertise in robotics, AI, data analytics, and automation will increase. Traditional manual labor roles may be replaced or redefined, requiring workers to acquire new skills and knowledge related to operating and maintaining robotic systems, analyzing data, and making informed decisions based on AI-driven insights. Upskilling and reskilling programs will play a crucial role in equipping the workforce with the necessary competencies for the future of gold mining.

Potential for Job Displacement and Retraining Needs

While robotic innovations bring numerous benefits, there is also the potential for job displacement in certain areas of gold mining. Automated drilling systems and remote-controlled robotic vehicles can reduce the need for manual labor, resulting in job losses. However, these advancements also create new opportunities for employment in roles related to robotics, data analysis, and system maintenance. To mitigate the potential impact of job displacement, it is essential to invest in retraining programs and support affected workers in transitioning to new roles within the industry.

Environmental and Social Implications

Robotic innovations in gold mining can have significant environmental and social implications, contributing to more sustainable and responsible mining practices.

Reduced Carbon Footprint and Ecosystem Disturbance

By optimizing resource utilization, reducing the use of chemicals, and implementing efficient machinery, robotic innovations in gold mining have the potential to reduce the industry’s carbon footprint. Advanced sensor technologies and AI algorithms can enable precise exploration and extraction, minimizing ecosystem disturbance and preserving biodiversity. Additionally, the use of alternative energy sources, such as solar or wind, can further reduce the environmental impact of mining operations, making them more sustainable and aligned with climate change mitigation efforts.

Community Engagement and Mining Practices

Robotic innovations in gold mining present an opportunity for enhanced community engagement and responsible mining practices. Mining companies can use advanced technologies to improve transparency, share information, and involve local communities in decision-making processes. Additionally, robotic systems can enhance safety measures, protect workers’ rights, and minimize social disruptions caused by mining operations. By prioritizing ethical practices, respecting cultural heritage, and engaging with local communities, mining companies can build trust and foster positive relationships, ensuring the long-term sustainability of their operations.

Collaboration and Partnerships

The development and implementation of robotic innovations in gold mining require collaboration and partnerships between mining companies, technology firms, and governmental organizations.

Joint Ventures between Mining Companies and Technology Firms

Collaboration between mining companies and technology firms is critical to drive advancements in robotic innovations. By combining the mining industry’s domain expertise with technology firms’ knowledge in robotics, AI, and automation, innovative solutions can be developed to address industry-specific challenges. Joint ventures can facilitate the sharing of resources, knowledge, and best practices, accelerating the adoption and implementation of robotic innovations in gold mining. These collaborations can result in cost savings, increased efficiency, and improved safety, benefiting all stakeholders involved.

Government Support and Funding for Robotic Innovations

Government support and funding play a crucial role in the development and adoption of robotic innovations in gold mining. Governments can provide financial incentives, grants, and research funding to promote research and development in this field. Favorable regulatory frameworks, tax benefits, and policies that facilitate technology transfer can encourage mining companies to invest in robotic innovations. Collaboration between governments and mining industry stakeholders can ensure adequate support and create an enabling environment for the widespread adoption of these technologies.

Conclusion

The future of gold mining is set to be revolutionized by robotic innovations. By leveraging robotics, AI, machine learning, and advanced sensor technologies, the industry can achieve safer, more efficient, and sustainable operations. The benefits of robotic innovations, such as increased safety for miners, efficiency improvements, lower environmental impact, and access to previously unreachable areas, make them invaluable in advancing gold mining practices. While challenges exist, such as the cost of implementation and regulatory hurdles, emerging technologies, use cases, and success stories highlight the immense potential of robotic innovations in gold mining. As the industry progresses, collaboration, skills development, and responsible practices will be vital to ensure a future of successful and ethical gold mining operations.